DISPLAY ENHANCEMENTS

Impact Components specializes in developing customized display solutions to our clients’ exact specifications. Our design and engineering teams have the technical skill and experience to bring your LCD display plans to fruition. No matter what LCD panel types you need (customized or standard), our goal is to always exceed your expectations. We are experienced in the following technologies:

TOUCH SCREEN INTEGRATION

Impact Components is a distributor of over 20 lines of touch screen manufacturers. Whether you need standard resistive and capacitive touch screens or have specialized requirements, we have your solution. Talk to our team about your specific application, such as use with gloves, rugged environments, clean rooms and more. Because we have the latest touch technologies including IR, SAW, and multi touch solutions, we are your one-stop-shop for the LCD touch screen monitor products you need. Examples of unconventional options include:

1. Projected Infrared Touch (15” to 70” diagonal)

PIT technology is a patented multi-touch technology. Compared to traditional infrared touch technology, PIT touch screen has slimmer bezel, lower elevated height, and better multi-touch experience. PIT touch screens support multi-touch capability, allowing more people to touch the screen simultaneously. This allows users to have a better interactive experience. Ultra-narrow bezel allows near-true flat appearance (as the touch transducers are placed under the screen). Optional protection enhancements include: waterproof or vandal-resistant.

Special feature: vandal resistant version of Projected Infrared Touch

With 4 mm and sometimes up to 6mm protection cover glass, rated IK09 which means they are protected against 10 joules impact (equivalent to impact of 5kg mass dropped from 200 mm above impacted surface).

2. Force Sensing Touch Screens (up to 32” diagonal)

Why Add Force Sensing?

An advantage of projected capacitive touch screens over other touch screen technologies is the ease of implementation of feather-touch & multi-touch for gestures, but feather-style touching can lead to unintended activations in conventional PCAP touch screens. Adding force sensing overcomes that weakness by implementing unintended touch rejection, ‘brushing off’ past accidents, and taking into account finger repositioning before selection. Force-sensing touch screen also enables new hand moves and menu-bringing features you can add to your product to enhance user experience.

Additional Advantages and New Movements Possible:

- ‘conductive’ fluids will not generate an unexpected touch event

- analog data for some applications eg. line width, velocity, “press-to-zoom” (“press-to-zoom” is a new user experience!)

- ability to control firing of haptics for real world feel using force threshold

- mouse emulation

- true single finger UI possible

- improved glove performance

- make unique shortcuts in OS with “peek & pop” movement

- two simultaneous users

- ‘stretched arm’ finger re-positioning

3. Curved Touch Screens for Gaming (21.5” to 49” diagonal)

Based on proven SAW touch technology, Impact Components has the capability of offering curved SAW touch screens in sizes of 21.5”, 27”, 32”, 35”, 42”. Furthermore, curved SAW touchscreens inherit and enjoy the benefits of SAW technology such as high reliability, protracted durability, sharp image clarity and vandal proofing. It’s the ideal touch solution for gaming and interactive kiosks.

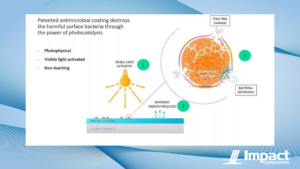

4. Permanently Germ-Free Touch Screen Monitors (10.1" to 50")

•Scientifically proven to eliminate up to 99.99 percent of harmful bacteria

• Delivering germ-free protection to touchscreen surface – permanently for life with no surviving bacteria left to reproduce

• A user cannot tell the difference between non-coated and coated surface as it does not affect reflection or glare

• It does not poison the bacteria on the surface of the touch screen, thus this technology is environmentally-friendly

• Perfectly safe to human skin as tested by German labs

• Hydrophilic, non-leaching, cannot be dissolved with water, easy to clean

• See comparison of Germ-Free solution from Impact vs Alternatives

• Click HERE for more information

SUNLIGHT READABLE DISPLAYS

So many applications demand a bright, vibrant, highly visible display in sun lit conditions. We address the need for bright displays through variety of innovative methods to enhance color, contrast, and brightness to maximize the clarity and impact of your message in very bright conditions. Don’t miss out on the new products based on latest technological advances in this area. Examples of unconventional options include:

- High-brightness customization for 4K/Ultra-HD resolution displays

- High-brightness customization for “bar” / “stretched”/ long-and-narrow display types

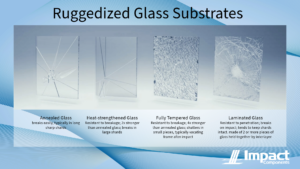

RUGGEDIZED SOLUTIONS

- Annealed Glass (not toughened, regular glass)

- Thermally Toughened Glass

- Chemically Strengthened/Tempered plain float glass

- Xensation glass (un-coated)

- Gorilla Glass 5

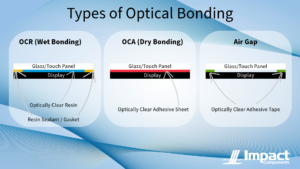

OPTICAL BONDING

-

1. Dry Bonding with OCA

To increase readability in direct sunlight we can eliminate the air gap between LCD and touch screen or protective lens using optical clear adhesive (OCA) lamination process. Dry bonding with OCA is an inexpensive bonding method with a reliable track record.

2. Wet Optical Bonding with UV Curing (up to 27” diagonal)

Wet bonding uses a heatless UV-curing process for optical bonding with a unique patented OCR (optically clear resin) bonding material (urethane acrylate) brought into a gel state in a Class 100 environment. Wet bonding ensures superior quality over infrared/IR curing techniques and solves any delamination concerns for customers compared to dry-bonding. The following options are available:

- Bonding to a touch screen of your choice to an LCD

- Anti-Reflective Lens (plain or chemically strengthened, single side or double side, 1.1, 1.6, 2.3, 3.0, 4.0, or 5.0 mm)

- Anti-Reflective & Anti-Finger Coated Lens (coated glass or polycarbonate for touch screen applications)

- AR/AG Glass (combination of Anti-Reflective coated and Anti-Glass, 812x635x1.6 mm standard sheet)

- AG Etched Glass (anti-sparkle fine etched anti-glare glass, single or double side options, chemically strengthened versions of 1.1, 1.6, 2.3, 3.0 mm)

- Chemically Strengthened Alumino-Silicate Glass (0.55, 0.7, 1.1, 2.0, 3.0 mm thickness)

- Micromesh EMI Shielding (with replicated micro conductive grid on PET, plastic, or glass, </-0.5 ohms per sq, 89% light transmission)

- Mesh EMI Shielding (with woven mesh optimized for displays with silver busbar termination, non-glare or hard-coated laminated polycarbonate, 1.5, 2.0, 2.5, 3.0, or 4.0 mm, max size 500x660 mm)

- </-5 ohms ITO-Glass EMI Shielding (</-5 ohms per sq indium tin oxide =ITO coated glass, 80% light transmission, 1.1 mm plain float glass, max size 550x850 mm)

- 12-15 ohms ITO-Glass EMI Shielding (12-15 ohms per sq indium tin oxide =ITO coated glass, 89% light transmission, 1.1 mm plain float glass, anti-reflective options, max size 550x850 mm)

- 15 ohms ITO Coated PET EMI Shielding (15 ohms/sq ITO coated PET, 80% light transmission, 175um thickness, 48” max roll width, PSA option)

3. Wet Optical Bonding with IR Curing (55” and up diagonal)

Performed in the U.S., Impact uses IR-curing process for optical bonding that involves infrared heat to bring optical silicone OCR material to gel state. Used to optically-bond touch screens of your choice or variety of lenses similar to options for UV curing listed above but excluding Micromesh option.

EMI MITIGATION

Many environments, such as aircraft and the medical industry are susceptible to the effects of electro-magnetic interference. We engineer a variety of solutions for EMI mitigation, to help reduce this type of interference. Don’t miss out on the new products based on latest technological advances in this field. Examples of options include:

- ITO-Glass or Mesh-Glass based EMI shielding - see section above about Optical Bonding for list of EMI shielding options

- EMI shielding along the perimeter of touch screens

INCREASED OPERATIONAL TEMPERATURE RANGE

While many standard displays are rated for -30C already, both displays and computer motherboards can be operational all the way to -40C with optional heaters. Heaters may be controlled via manual adjustment or automatically when paired with thermistors.